Circleblast Internal Pipe Cleaners

The Circleblast Internal Pipe Blasters are designed to blast clean pipe ranging in size from 1¼” to 12” (13 to 305 mm) I.D. The tool connects to an abrasive blast machine in place of a standard nozzle. In operation, the Circleblast nozzle directs the air/abrasive mixture at a deflection tip. This tip causes the blast pattern to fan out into a wide, circular pattern, which cleans the inside of the pipe as the tool is passed through. Two centering devices are available to hold the tool in position during passes.

The Circleblast tool is made from the finest materials available. However, some of its internal wear parts are of necessity rather brittle, due to their extreme hardness. The tool should therefore be handled carefully to avoid

dropping it or giving it a sharp blow.

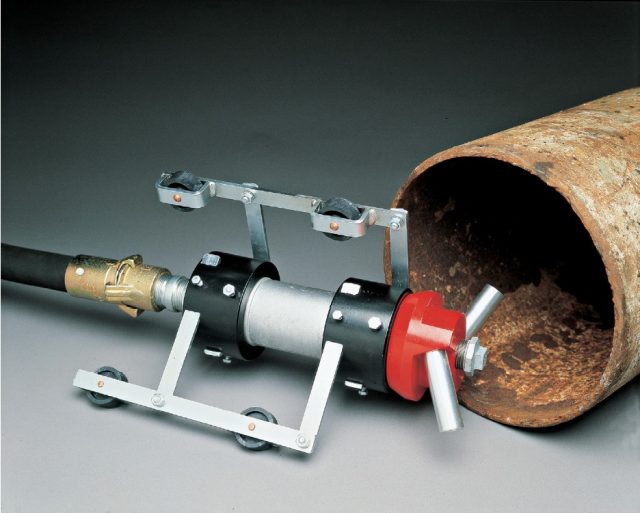

The Spinnerblast tool cleans the interior of pipes up to 40’ long and ranging in size from 8” (203 mm) to 36” (915 mm) I.D. The tool connects to most abrasive blasting machines in place of a standard nozzle.

The Spinnerblast tool cleans the interior of pipes up to 40’ long and ranging in size from 8” (203 mm) to 36” (915 mm) I.D. The tool connects to most abrasive blasting machines in place of a standard nozzle. The Jumbo Internal Pipe Blaster tool cleans the interior of pipes up to 40’ long and ranging in size from 1016 mm (40”) to 1930 mm (76”) I.D. The tool connects to most abrasive blasting machines in place of a standard nozzle.

The Jumbo Internal Pipe Blaster tool cleans the interior of pipes up to 40’ long and ranging in size from 1016 mm (40”) to 1930 mm (76”) I.D. The tool connects to most abrasive blasting machines in place of a standard nozzle.